CONTACT US

Laiwu Yida Materials Technology Co., Ltd.

ADD:No. 191 Wudangshan Road, Laiwu High-tech Zone, Shandong Province

電話:0531-76251099

手機:0531-76251091

Email:lwxylc@163.com

Web:www.studioponk.com

XD Active Porcelain Ball

Product Characteristics and Application Scope

XD active ceramic balls are prepared by introducing a small amount of transition metal oxides into inert alumina ceramic balls. It not only has the characteristics of high temperature resistance and high mechanical strength of inert alumina ceramic balls, but also has the functions of filtering, dispersing vapor and liquid, covering and supporting catalyst, and has certain catalytic activity. In the process of olefin oxygenation, desulfurization, denitrification and benzene hydrogenation, filling active ceramic balls on the top of catalyst bed in the reactor can make the monoolefins and diolefins in the secondary crude oil get preliminary results. Hydrogenation can reduce the heat build-up of catalysts. Filling active ceramic balls at the bottom of the catalyst bed can remove mercaptan produced in a certain reaction process. Therefore, the use of XD active ceramic balls can not only effectively improve the space utilization rate of the reactor, but also, to a certain extent, protect the catalyst from poisoning and sintering and prolong the service life of the catalysts.

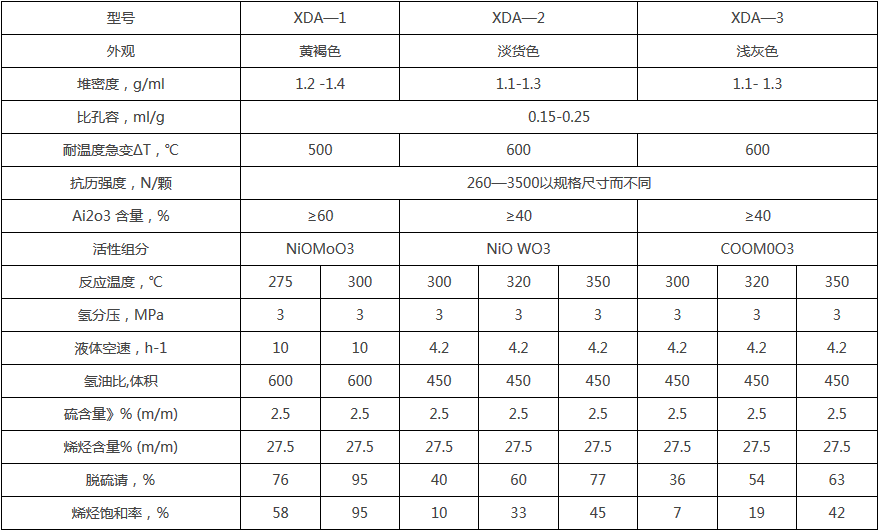

Physicochemical performance indicators:

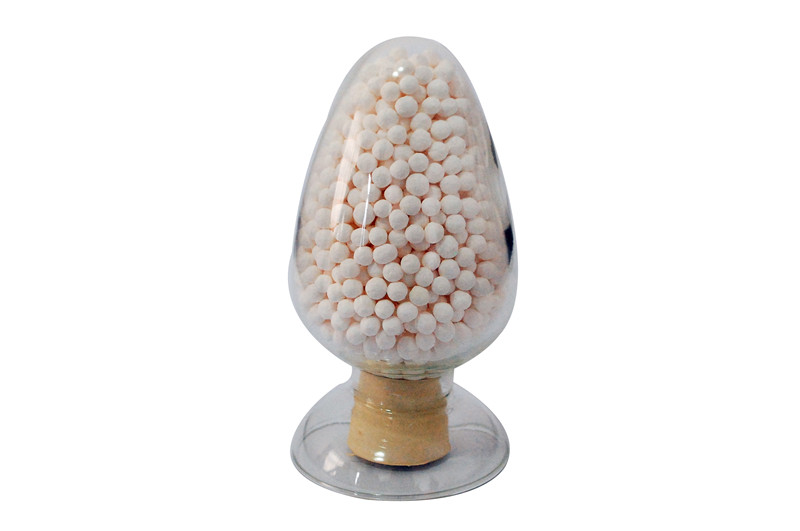

Specifications:

Activated ceramic ball size is divided into 12 varieties, and according to its nominal diameter is divided into 6, 8, 10, 13, 16, 20, 25, 30, 50, 60, 75. Other shapes and specifications can be produced according to user design requirements.

Packaging and precautions:

XID active ceramic balls are packed in plastic woven bags and lined with plastic bags. The net content of each bag is 25 kg. They are lightly loaded and unloaded during transportation to prevent product damage. Storage should be careful to prevent dampness.